Warehouse

Warehouse management: the heart of the system

The module contains the functions aimed at identifying the items in the warehouse according to the lots to which they belong. Thanks to the batch warehouse management, the various materials can be identified according to the purchase or production batch or by internal coding.

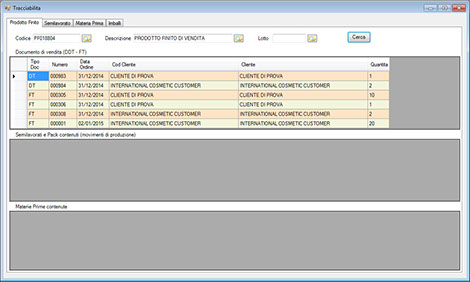

Each single item can be managed both with reference to its total stock and with reference to the individual lots that make up that particular stock: in this way the operator will be given the right to extract consultations, prints, processing based on the lot, with the consequent possibility of easily checking the correspondence of the lots to the respective purchase or sale documents.

Through the batch management that TECHNICS allows, both the necessary product traceability and the need for quality oriented product management are largely safeguarded.

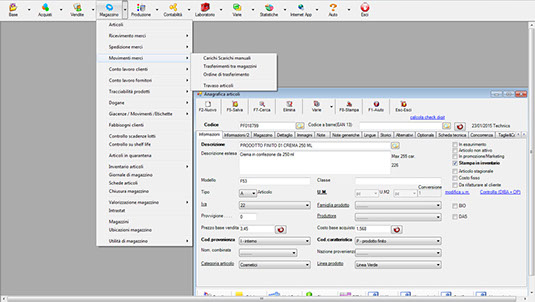

The article data base provides the operator with a large amount of information. To give just a few examples, a distinction will be made between the usual and alternative suppliers (including their delivery days and purchase costs), information on minimum batches and lead times, alternative items (reported in production) and much more.

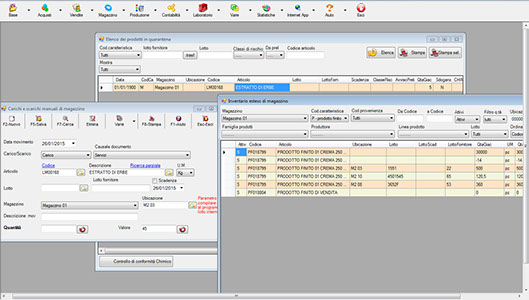

Quarantine products

A peculiarity of cosmetic companies is the need to manage quarantine in compliance with conformity checks for incoming goods or goods produced internally. TECHNICS also has this type of function, which is equipped with both the automatic fast release and the drafting of a real quality control.

TECHNICS, through appropriate parameters, allows the possible quarantine of products based on type and/or origin.

Starting from version 4.0, TECHNICS is able to manage product recontrols, parameterizing the way of working in detail. For example, it is possible to establish base expiry and/or recheck days for product families, or to combine different information for each individual item.

Lot expiry check

Thanks to a special function of TECHNICS it is also possible to keep under constant control the deadlines of the products in stock, whether they are raw materials, semi-finished or finished products. Even in production, TECHNICS warns of the presence of raw materials that have expired, thus relieving the operator of incessant and risky manual checks and consequently improving the fluidity of the processes.

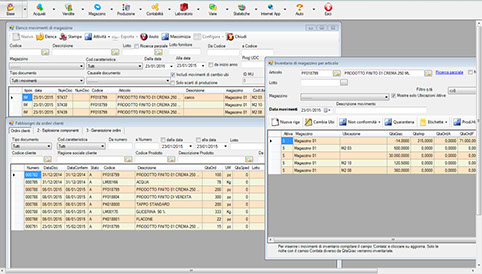

Goods handling and control

The warehouse module includes all the types and functions necessary for the management of outgoing and incoming goods, the manual management of warehouse movements and the function for transfer between different warehouses.

Issuing DDT, printing invoices, loading goods into stock is really very simple: thanks to a few clicks you will be able to easily retrieve orders and / or quotations, which can then be transformed into tax documents, without having to re-enter every time entries or codes.

Laboratories working on behalf of third parties will find it very helpful to manage the customer work account with orders, loading and shipping of goods (including their value).

It is instead to the laboratories that use subcontractors that the complete management of the suppliers' work account is addressed, including the request for quotations and orders, the schedule, the management of external production with transfers between external/internal laboratories, so as to enable the operator to manage the handling of goods with punctuality and efficiency.

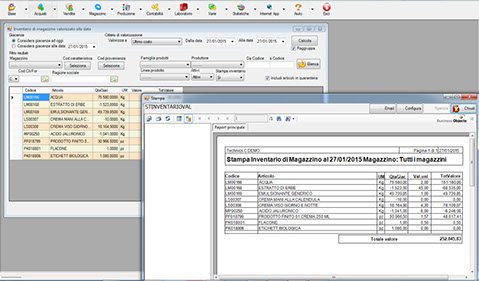

Item and Product History Stock Information

TECHNICS constantly assists and supports the operator during all work phases, providing targeted and precise information about stock and commitments (orders and production) and also providing a real-time analysis of stock trends and the time projection of commitments.

All useful data will be accessible to the operator with just a few clicks, thus avoiding the burden of consulting several programs to obtain the necessary information.

© Technics Cosmetics S.r.l - VAT N. 02243460207 - Phone 0131-941812 - info@technics.it © 2018